In the previous article, I found out there were some mistakes on the PCB of an omni-wheel robot. Here, I present the PCB design modification. My works is supported by PCBWay.

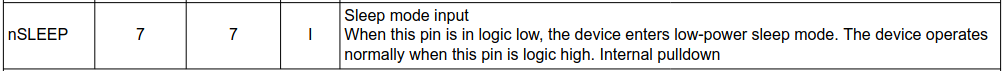

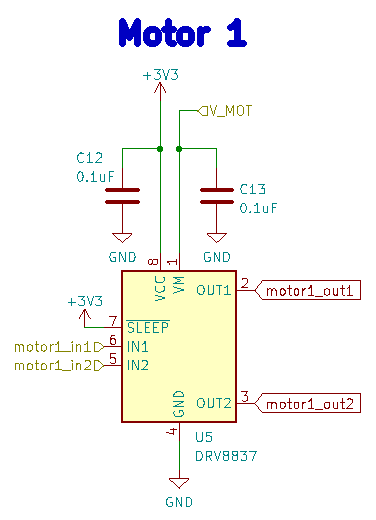

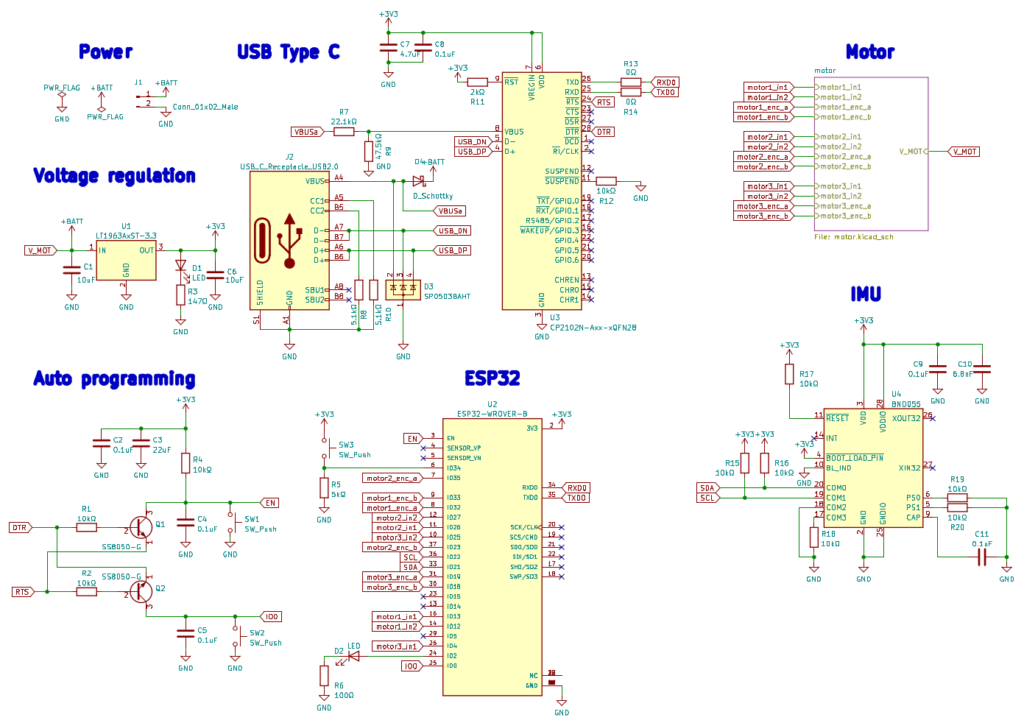

Connect nSLEEP PIN of DRV8837 to HIGH

As the following date sheet shows, I needed to input HIGH to the nSLEEP PIN in order to activate the DRV8837 motor driver.

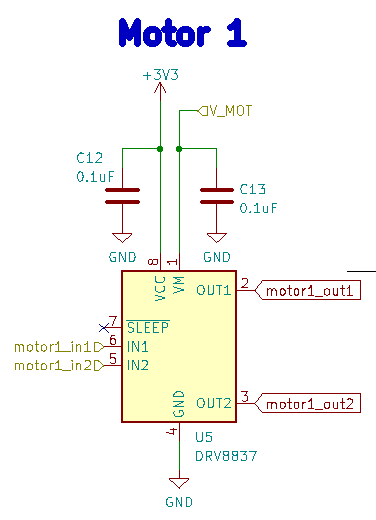

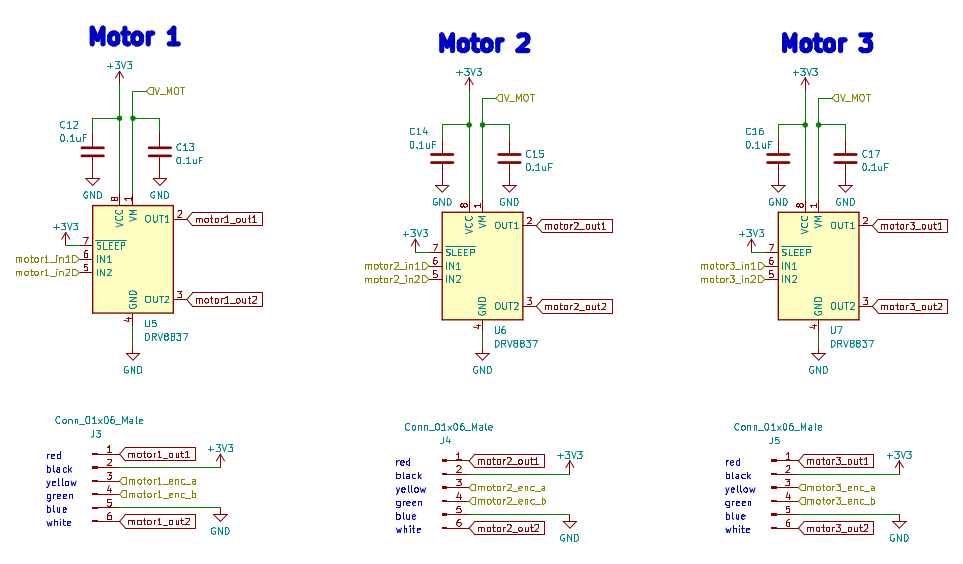

The left-side circuit is the original one and the right-side shows the modified circuit.

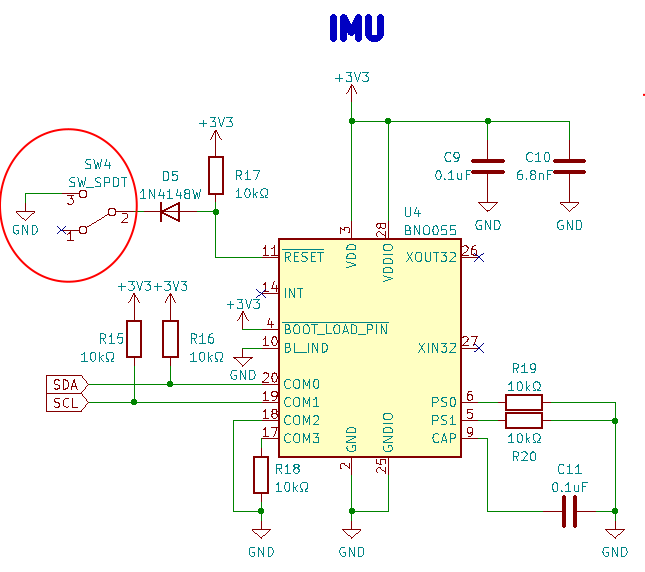

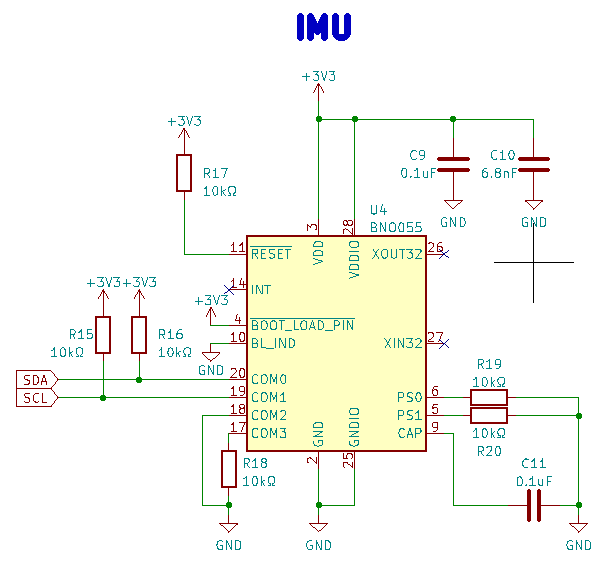

Do not use the config mode of IMU

I designed a switch between “config” and “operation” modes in the previous circuit. However, we usually do not use the config mode, so I delete the switch.

Reverse polarity protection (not add this time)

I decided not to add reverse polarity protection because

- The LDO regulator LT1963 (datasheet) has reverse current protection

- The motor driver DRV8837 (datasheet) has overcurrent protection

- Counter-measures for reverse polarity protection cause the voltage drop or need to add a fuse, and we need to replace a fuse when someone misconnects a battery.

There are two major methods to protect reverse polarity. The first one is using schottky diode, and the other is using a P-MOSFET (reference). The latter method results in a smaller voltage drop, but either method results in a voltage drop.

For our usecase, the P-MOSFET should satisfy the following conditions, and ChatGPT recommended AO3401A.

| Item | Conditions should be satisfied |

| Maximum Drain Current | At least 6A |

| On-Resistance | 50mΩ or less (to achieve a forward voltage drop of 0.3V or below) |

| Gate Drive Voltage | Must reliably work at 3.7V (Lipo Battery 1-Cell) |

| Package | 3-Terminal P-MOSFET |

Furthermore, there is a way to add a fuse and a diode in the reverse direction. In this case, we must replace the fuse when someone connects a battery incorrectly.

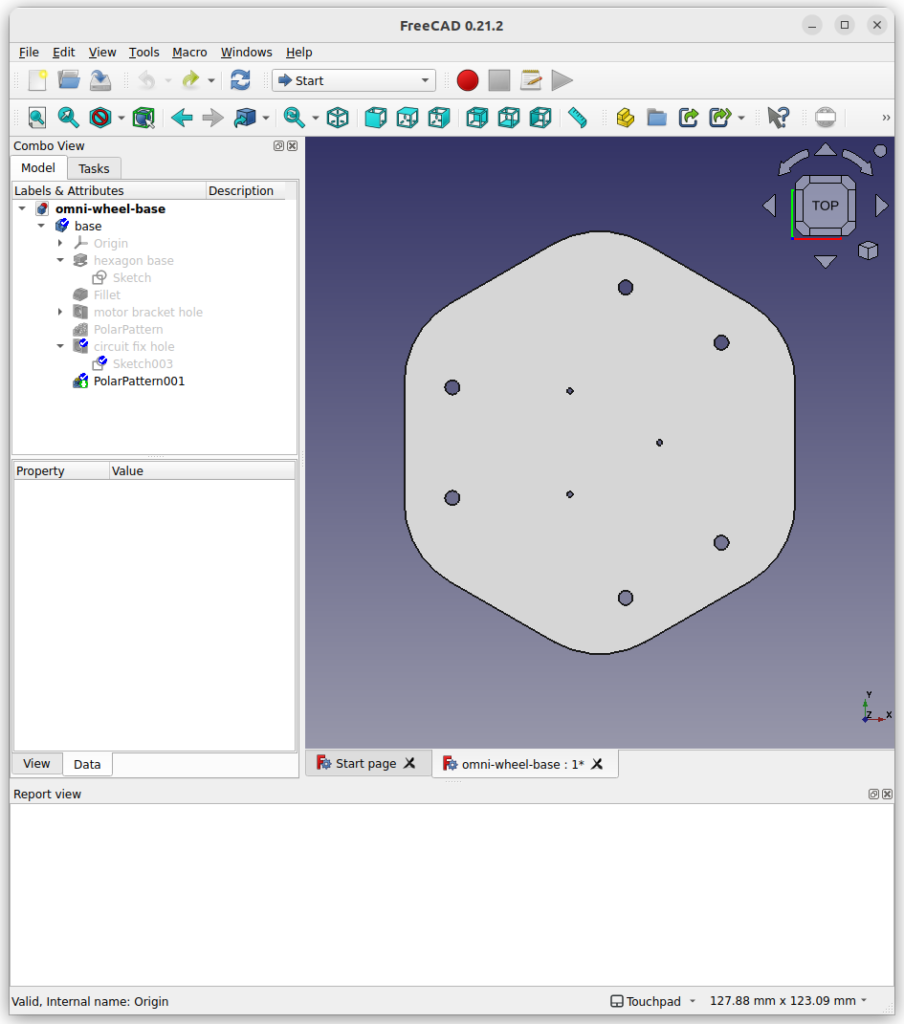

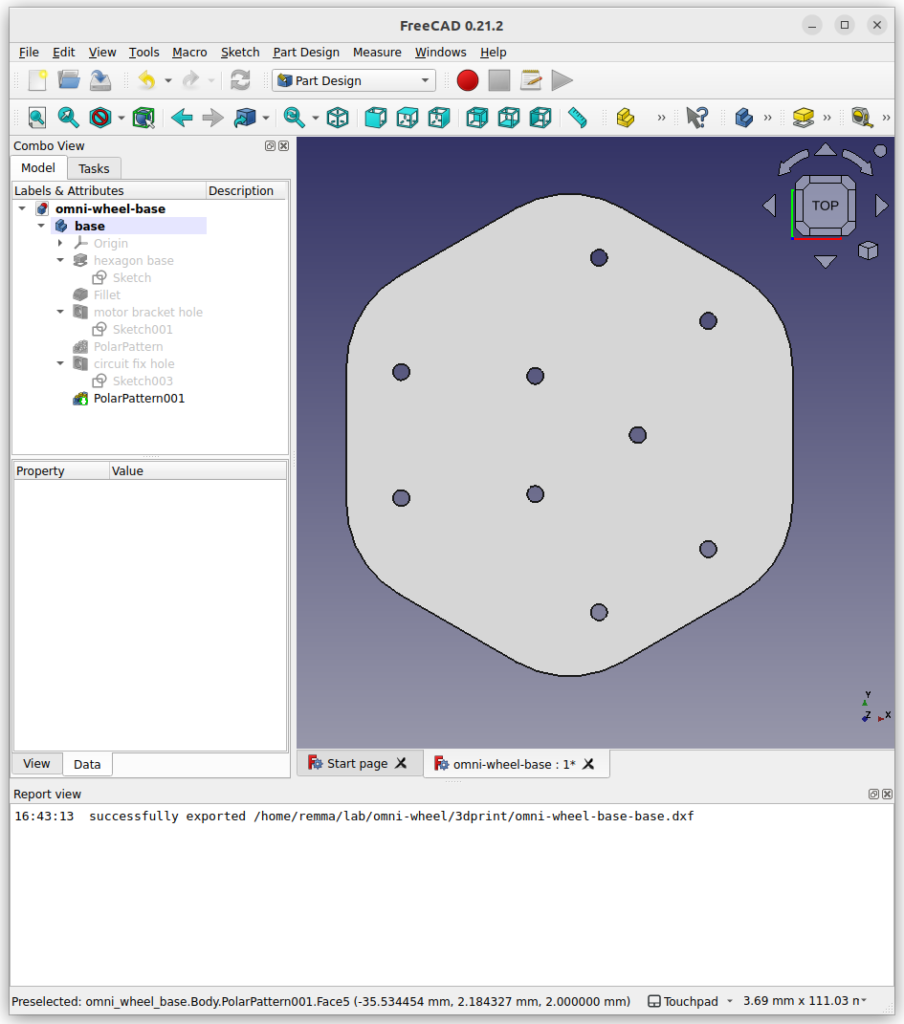

Widen screw holes

The holes at the center were too small for M3 screws. Thus, I widen them.

Reverse the motor PIN direction

Previously, the cables for motors needed to be twisted because of the PIN direction. I fix the direction by PCB design.

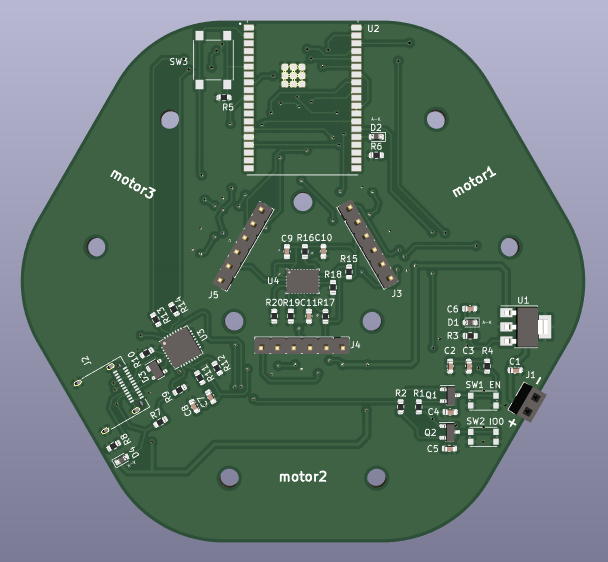

Finalized design

Schematic

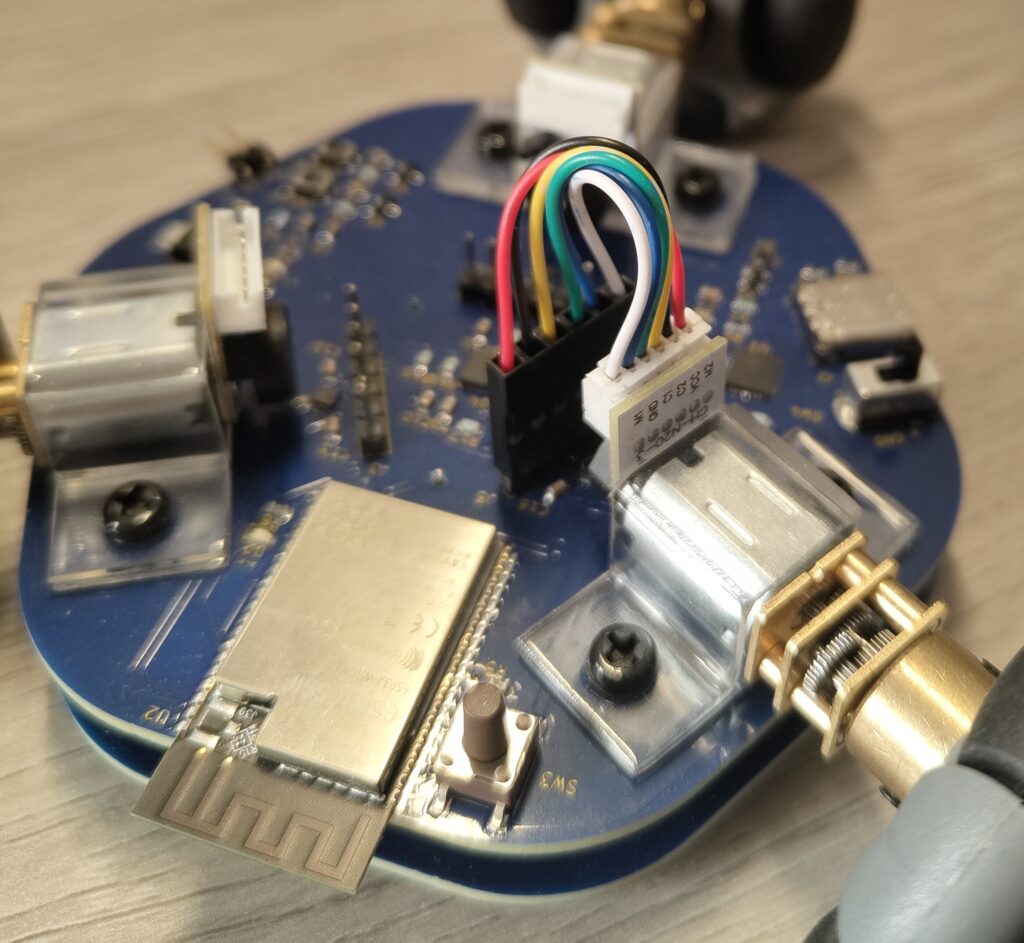

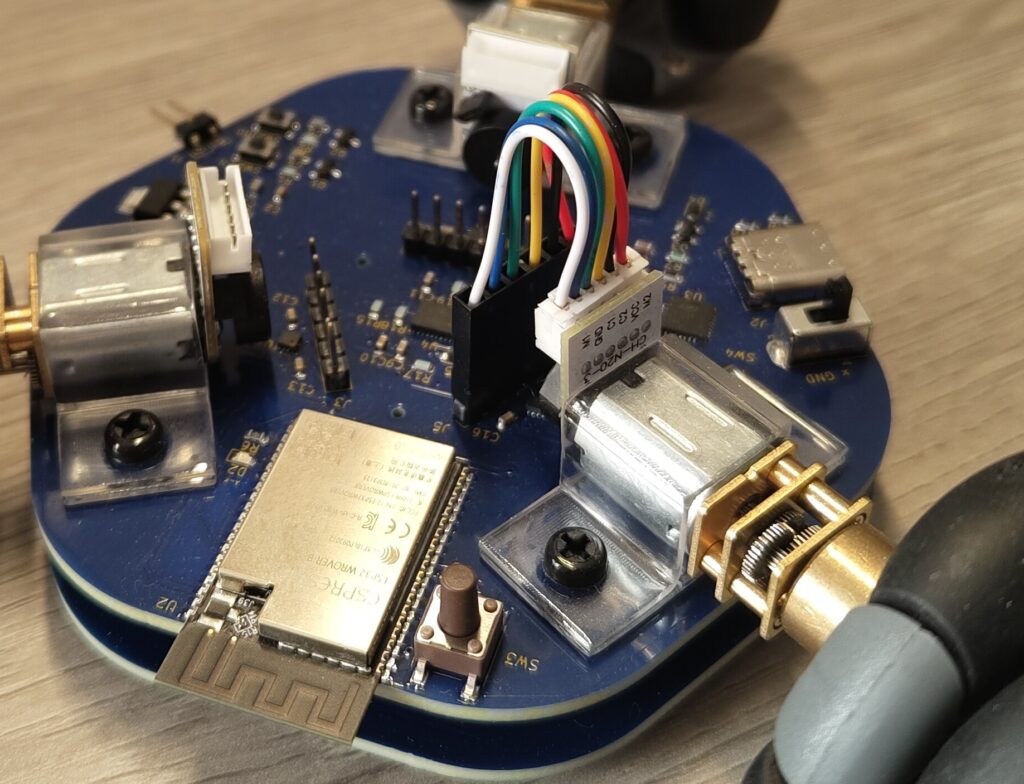

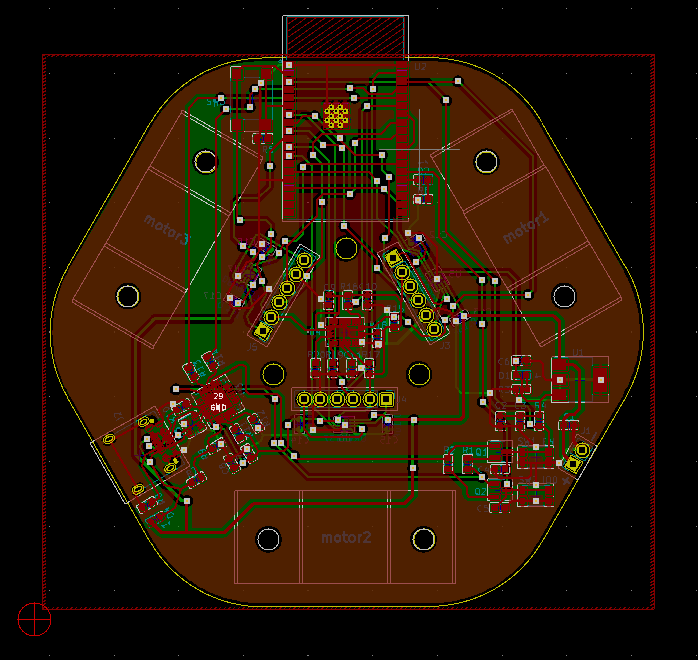

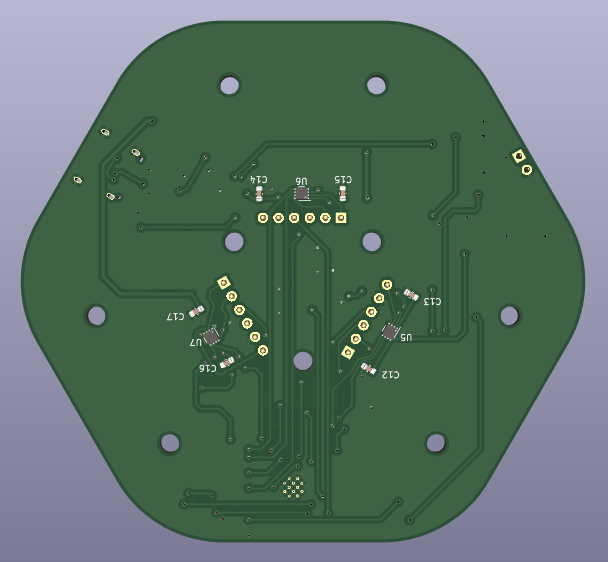

PCB design

I have redesigned the PCB while keeping the following in mind.

- Place components on the PCB to avoid crossing traces.

- Motor drivers are located at the back layer.

- Spaced the components sparsely to make it easier to place vias.

Ordered material

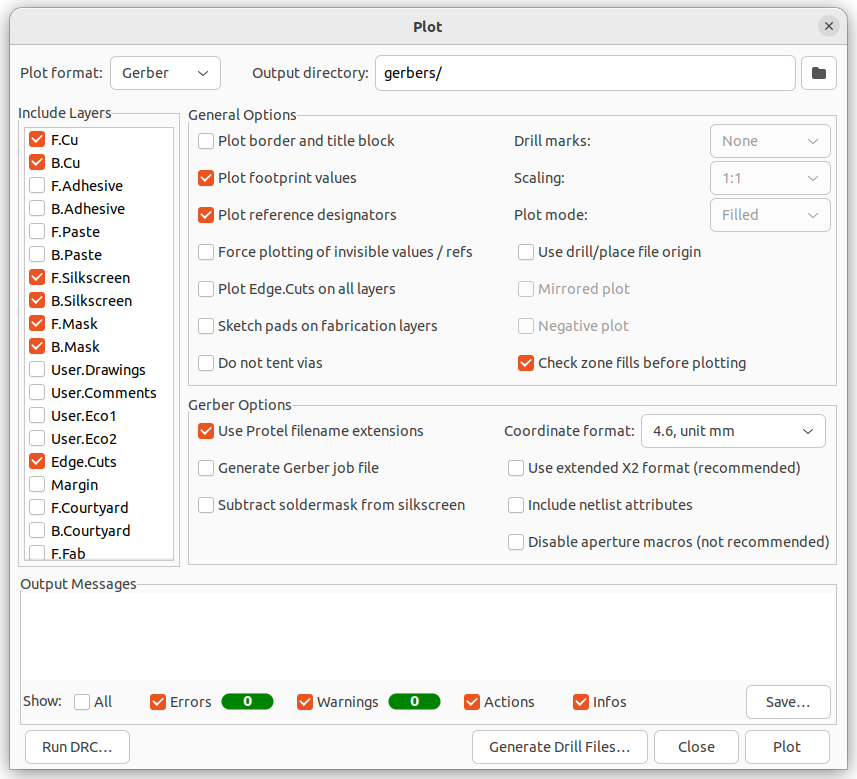

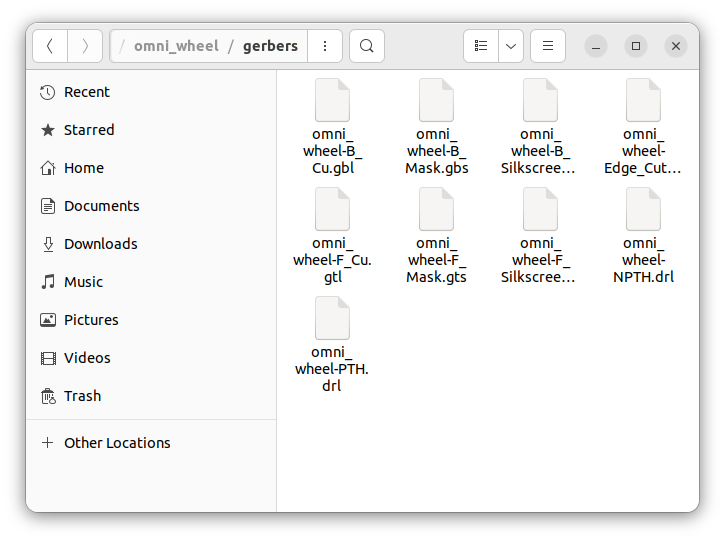

gerbers data

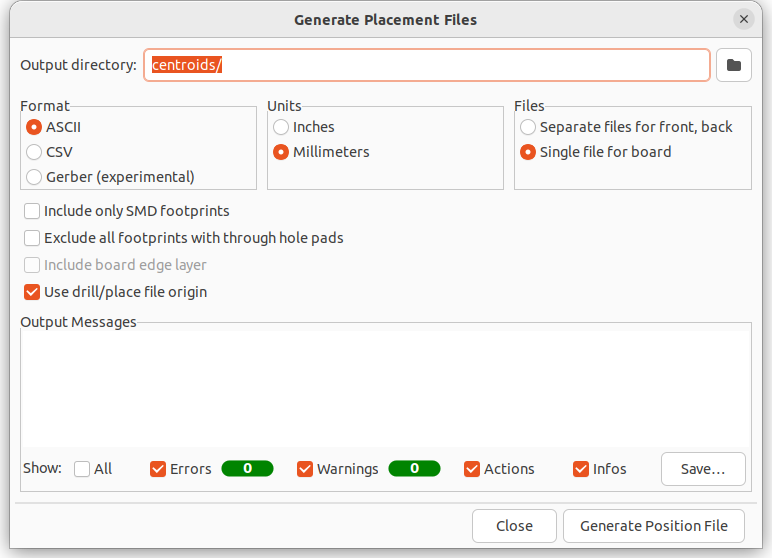

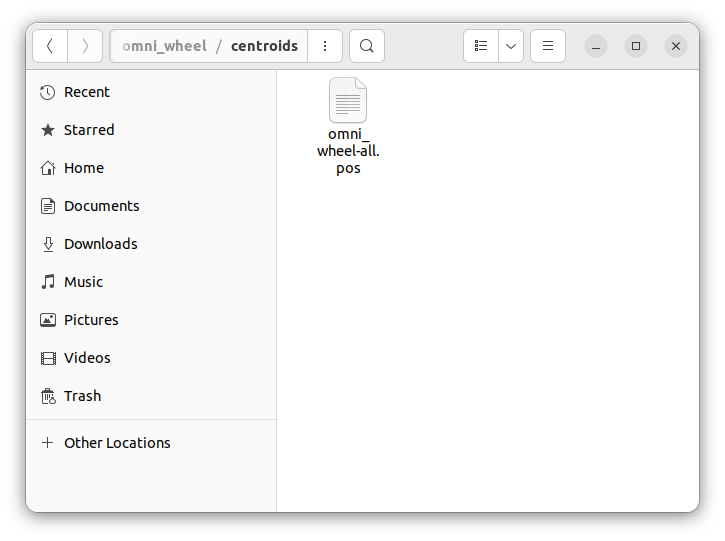

centroids data

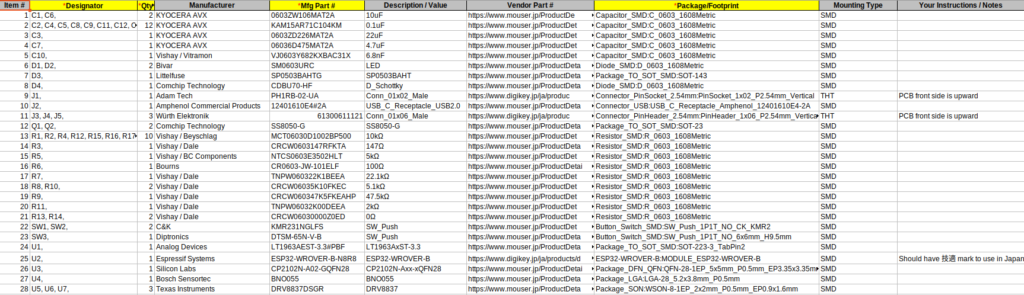

BOM

Summary

Wrote an article on PCB design modification. Hope these changes make a robot work.

コメント